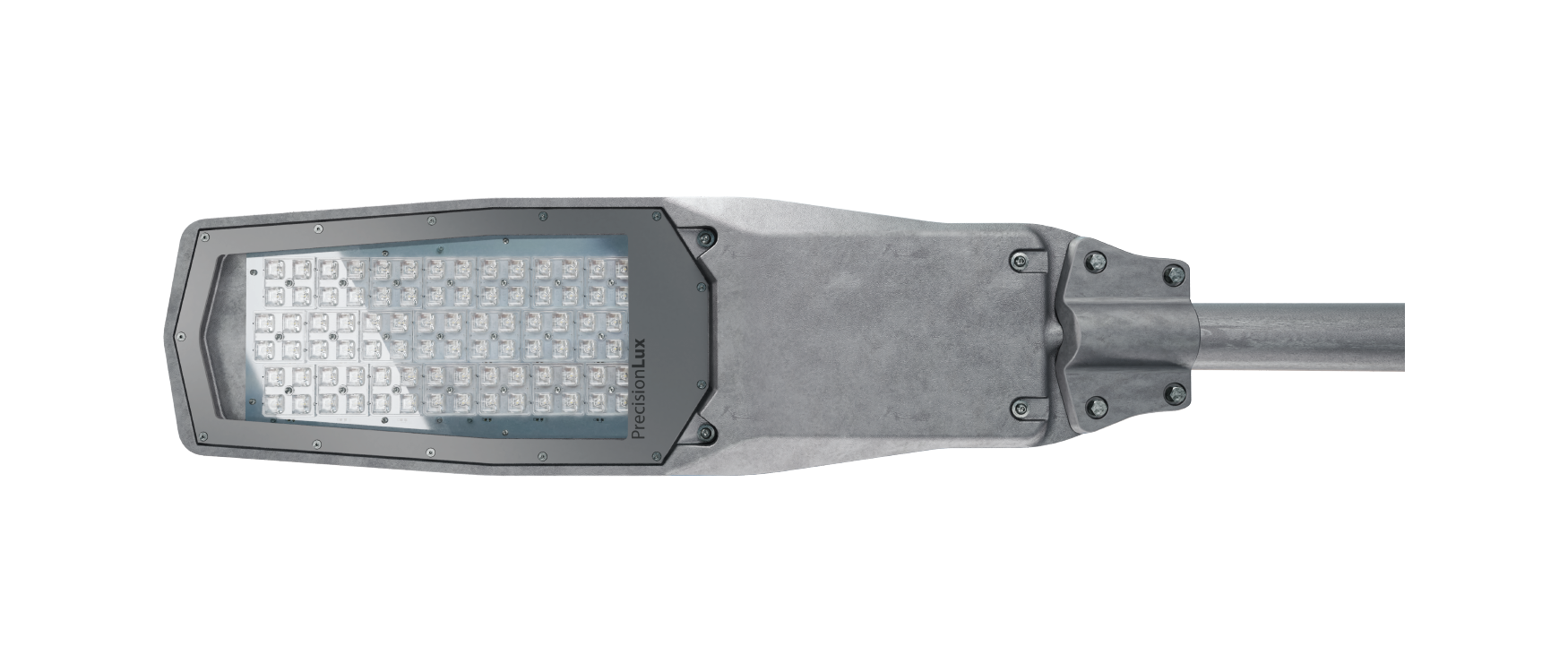

PrecisionLux 3™

SKU: 98LUCKY150SMD

- Power supply / Efficiency: 100-240VAC, 50Hz / >90%

- Total power (W): 120

- Power factor: >0.95

- Efficacy (lm/W): 110

- Luminous flux (lm): 14350

- Light temperature / CRI: 2700-4500K / >80 (depends on light colour)

- Operating temperature (°C): -30°C to +45°C

- Cover/Housing: 4 mm thick polycarbonate or 5 mm thick tempered glass / Aluminium alloy

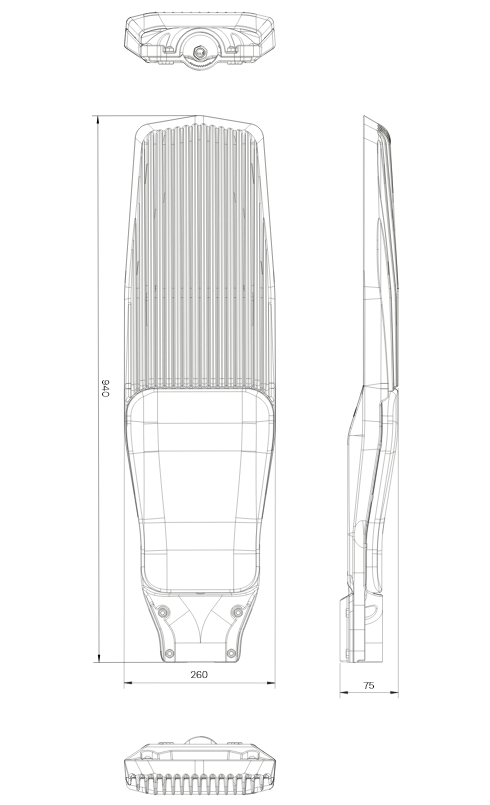

- Weight/Dimensions (LxWxH): max. 14kg/940x260x75mm

- Light socket diameter: 58-70mm

- Certificates: CE (LVD and EMC), ENEC, IP66, IK09, ANSI C136.31

DESCRIPTION

The wide power range of PrecisionLux3 lights (60-180W) and the ability to dynamically regulate the light flux intensity make it an ideal choice for residential lighting. This light has significantly reduced energy consumption with excellent light distribution compared to conventional lighting and a service life of over 100,000 hours. The warm colour light with flexible and precise light distribution, simple plug & play modular design and the ability to communicate with the PrecisionLeap system for remote control and monitoring of the lighting make this light an ideal choice for all types of roads. The PrecisionLux 3 light is 100% environmentally friendly and does not contain harmful substances.

INSTALLATION

The light is mounted on an arm with a diameter of 58 to 70mm.

To install the light, first remove the protective cover (glass or polycarbonate) by unscrewing the M3 screws on the underside of the light. Carefully hold the cover to prevent it from falling out. Thread the power cord through the tube carrying the light and insert it into the light through the fitting at the rear end of the light. The permissible outside diameter of the cable is in the range of 8-13mm. The dimension of the fitting is M20.

The standard cable for powering the light is NYY (PP00), as follows:

– 3×1.5mm2 in class I electrical protection

– 2×1.5mm2 in class II electrical protection.

Tighten the fitting sufficiently to prevent the cable from moving when pulling by hand.

After the cable is threaded through, the L, N and PE (GND) lines must be connected to the marked L, N and PE (GND) terminals inside the housing. In the case of a class II electrical protection light, it is sufficient to connect lines L and N. The terminals are spring type and are designed for tool-free connection.

Return the cover to the bearing and press it against the seal with reasonable force (approx. 20N). Tighten the 4 bracket fastening screws with 1.5Nm torque and continuous hand pressure on the cover to ensure the best sealing of the cover. Clamp the tube to the housing using the supplied clamp and 4 M8 screws. The screws pass from the lower side of the clamp, with a washer, elastic washer and nut placed on the screws on the upper side of the housing. The tightening torque of the nut is 10Nm.

SAFETY

1. In the event of a malfunction or any fault with the light, contact the manufacturer or a service technician.

2. In accordance with the EN 62778 standard, the PrecisionLux series of street lights belongs to Product Group 1 (Risk group 1).

3. The light source (LED module) of the light can be serviced (replaced) only by the manufacturer, an authorised service technician or other professionals authorised by the manufacturer.

4. Installation and maintenance of the PrecisionLux series of lights is only permitted by trained personnel or electricians authorised by the manufacturer. Failure to follow these guidelines could result in serious injury or death.

5. Any modification to the light beyond the installation instructions is strictly prohibited. Failure to do so will void the warranty.

6. Opening the lights in any case outside the prescribed maintenance voids the warranty and is not recommended.

Next product

LED LIGHTING